FSW MACHINE

FULL SERVICE

FRICTION STIR WELDING MACHINES SOLUTON AS WHOLE ENTIRE LIFE

Whether you are looking for standard machine or special complex machine, UNIVERSAL FSW will develop your different product using processes that have been proven many times over. From initial contact process ideas and design through to manufacturing and installation of the machines and beyond 7/24 service and maintenance, we will accompany you as your equal partner in turning your requirements into technical solutions and develop high-performance equipment.

Requiring the customer demands is our top priority job.

The FSW experts at UNIVERSAL FSW support you with technical solutions and optimal FSW process

Our machine designs focus on reasonable design. Machine functionality (ability and accuracy), stability, safety, humanization (ease of operation)

We have the most professional machining equipment and the most excellent technical skill staff. base on this, making ensure the excellent quality of equipment parts were made by own.

Rely on the global industrial center – Shanghai, we can quickly solve the procurement equipment parts from any other country

Make sure there are no gaps on machine. mechanical assembly is an important process to determine the quality of machine. According to the design requirements of the equipment. we will first connect the standard parts step by step and then set up the whole machine.

In whole assemble period. highly trained and skilled staff always serve for you

Efficient and reliable systems depend on more than good quality installations. we will also carry on a series of tests on the equipment, including machine function, accuracy and customer product samples test. After successful factory testing. We will provide the machine certificated for customer.

We will accompany you throughout the entire product lifecycle.

We provide training for machine operation and routine maintenance service that gives you a thorough understanding of your equipment and the systems they operate in. if have any questions on machine, we accept rapid response and give feedbacks as quickly as possible.

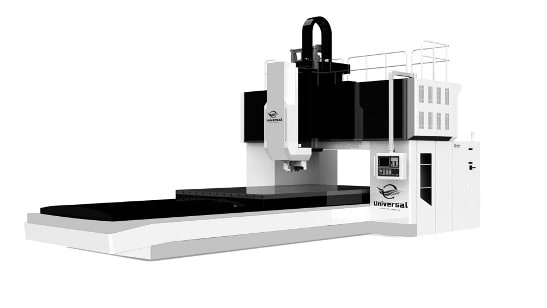

FSW-Table Style Machine

- The abbreviation T-FSWC stands for “table friction stir welding center.

- The Table FSW center machine is a machine tool for the welding of smaller components in the automotive industry.

- This machine is easy to operate and is characterized by good handling. This makes it perfect as an entry-level series but also suitable for small series production(heat sinks,gearbox and cold plates).

MACHINE ADVANTAGE:

- High stability professional casting machine body

- Siemens System

- FSW Spindle

- Force measurement system

- FSW process data collection and monitoring

SPECIFICATION DATA:

Stoke

X-axis: up to 1,500mm

Y-axis: up to 800mm

Z-axis: up to 500mm

Speed

X-axis: 10,000 mm/min

Y-axis: 10,000 mm/min

Z-axis: 3,000mm/min

Tilt angle

C-axis: +/– 360°

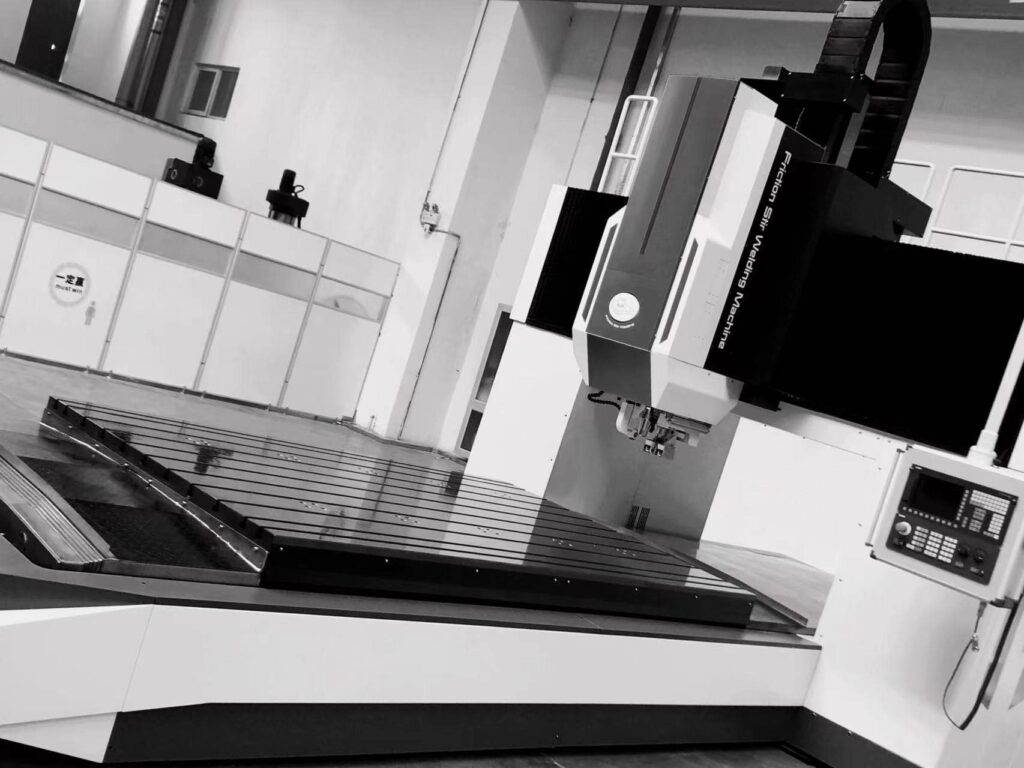

FSW-Gantry Moving Style Machine

- The G-FSW Series machines are the most popular machine in friction stir welding especially in automotive industry for battery trays.

- It allows you to easily produce simple welding(1-D,2-D) with sheet thicknesses of up to 25 mm.

- The G-FSW series are designed as 3-Axis machines in gantry design and can be upgraded to up to 5-Axis.

MACHINE ADVANTAGE:

- High stability professional casting machine body

- Siemens SINUMERIC 840D SL

- FSW Spindle

- Force measurement system

- Drive parts positioning accuracy 0.03mm/1000mm

- FSW process data collection and monitoring

SPECIFICATION DATA:

Stoke

X-axis: up to 8,000mm

Y-axis: up to 4,500mm

Z-axis: up to 600mm

Other travel lengths also available on customer request.

Speed

X-axis: 10,000 mm/min

Y-axis: 10,000 mm/min

Z-axis: 3,000mm/min

Tilt angle

C-axis: +/– 360°

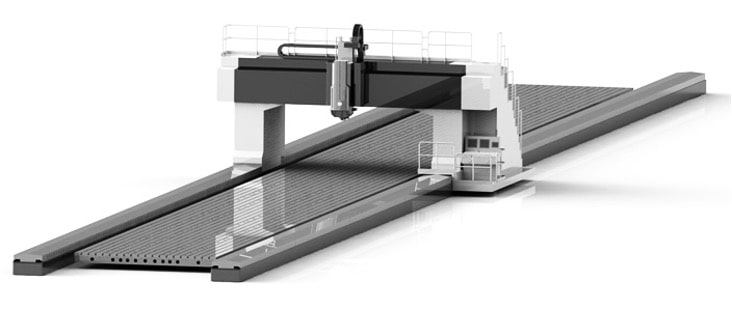

FSW-Gantry Moving Style Large Machine

- The G-FSWL series is a large-sized 5-axis FSW machine for processing of large components in aerospace, railway, shipbuilding and many more. It is also available as a combination for milling and FSW. It has an integrated automatic tool changing system.

- The welding sheet thicknesses of up to 100 mm , Travel speeds of up to 40 m/min, Improving welding speed and running speed is the key to the use of large sized equipment.

MACHINE ADVANTAGE:

- High stability professional casting machine body

- Siemens SINUMERIC 840D SL

- FSW stand shoulder

- The option to add milling

- Retractable Pin-Tool and Bobbin tool welding

- Force measurement system

- Drive parts positioning accuracy 0.03mm/1000mm

- FSW process data collection and monitoring

SPECIFICATION DATA:

Stoke

X-axis: up to 80,000 mm

Y-axis: up to 6000 mm

Z-axis: up to 600 mm

Other travel lengths also available on customer request.

Speed

X-axis: 10,000 mm/min

Y-axis: 10,000 mm/min

Z-axis: 3,000mm/min

Tilt angle

C-axis: +/– 360°

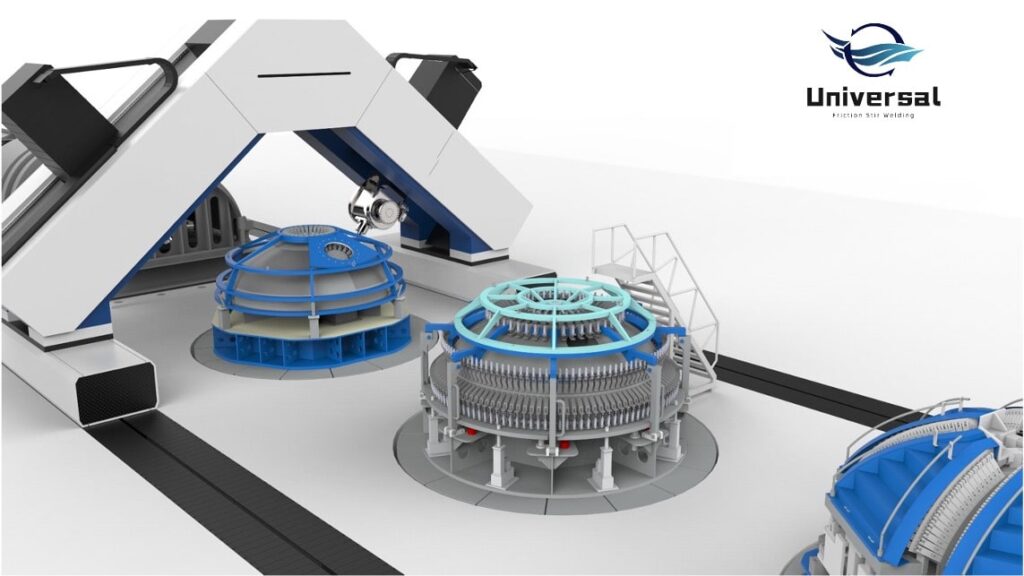

Special-FSW Machine

- We provide Special-FSW machine and solution for customer request.

- We also provide High process functionality and stability FSW machine for our customers. as well as high-level machine are the necessary requirements we apply in the development of special-FSW systems.

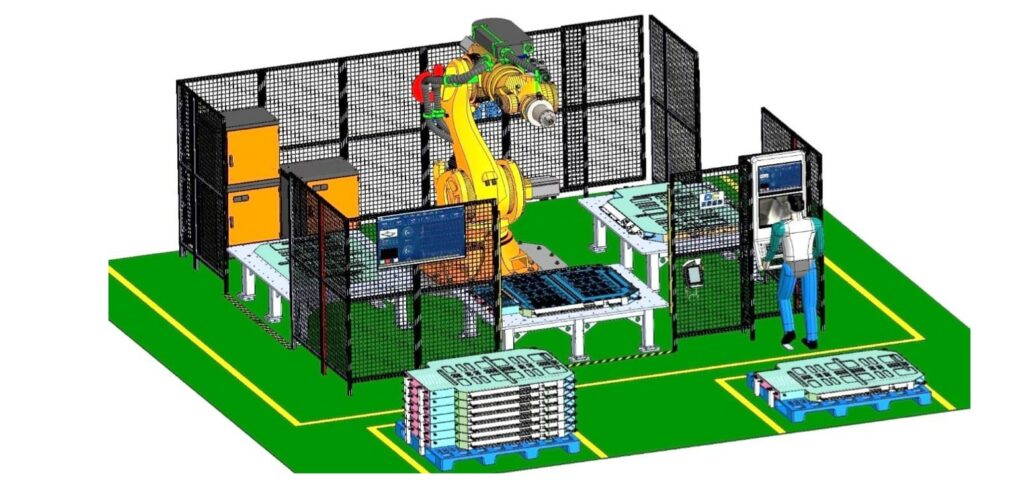

FSW-Robot System Innovation FSW Solution in the future

- UNIVERSAL FSW not only provide for machine but also for flexibility welding robot system.

- Normally, the type of friction stir welding machine are limited by working space and only fulfill the welding requirements of linear or two-dimensional products, but it can not weld requirements of complex structural parts.

- Compare with traditional FSW machine, there are variety of advantages on Robot system, such as It have high flexibility and High process stability which can easy to weld complex structure products. Moreover,it have high degree of automation with six- axis. Further, it have high efficiency with 7/24/365 in any industrial.

MACHINE ADVANTAGE:

- High process stability

- Stationary tool

- Force control and Distance control

- Weld seam tracking

- HSK Tool

- Tool management

SPECIFICATION DATA: